What Is a Sandwich Panel Used for in Construction?

Although you may not have heard of them before, sandwich panels are types of construction material that have been around in since at least the 1940s. Their popularity and use has increased exponentially since then, now being one of the most used materials for buildings and other construction projects. These composite construction materials are ideal for replacing facades with exposed, hidden or architectural screws.

At thedailyECO, we learn more by asking what is a sandwich panel used for in construction? We also explain the benefits of sandwich panels to explain why they have become so popular.

What is a sandwich panel in construction?

Also called composite panels, sandwich sheets or polyurethane panels, sandwich panels are a type of construction material used increasingly in various types of building construction. This is due to their practicality and versatility, allowing them to fit into almost any type of building where needed.

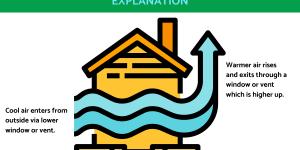

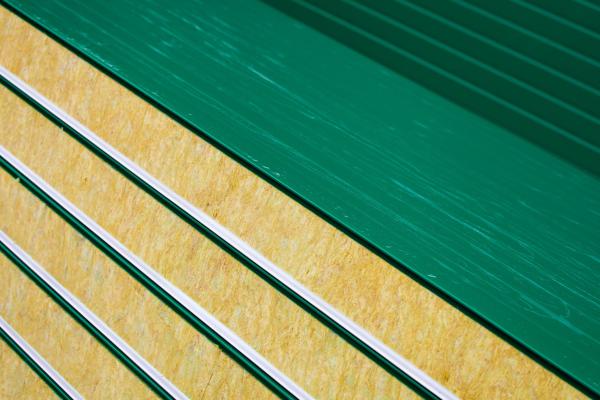

The sandwich panel is basically made up of two outer sheets and a core. This core is made up of an insulating material such as polyurethane, mineral wool or other similar materials. Its name derives from its main characteristic which is its sandwich structure. These panels provide shape, resistance to weather and rigidity in construction, as well as insulating properties, both thermally and acoustically.

This type of panel originated after the Second World War with the aim of satisfying the needs protecting room temperatures due to its excellent thermal insulation. Since this original usage, sandwich panels have now become a revolution in construction systems. We can find them used in steel structures required for various buildings in commercial, agricultural or residential settings.

Benefits of sandwich panels

As we have pointed out, the sandwich panel has become a fundamental material in any construction company, although this does not mean they are necessary for all construction projects. Their popularity is due to various advantages over similar construction materials. These advantages of sandwich panels include:

- Protection against water, steam and air tightness.

- Excellent thermal insulation.

- Excellent acoustic insulation.

- Their outer metal plates resist the most aggressive atmospheric agents.

- High resistance and low weight.

- Assembly is very simple, so it allows you to build structures very quickly.

- Its repair or replacement is easy.

- As a mass-produced product, it is often very cost-effective material for projects of varying budgets.

- Its useful life is long and its maintenance cost is low.

- Mineral wool core panels are fire resistant.

- There is the possibility of placing a sandwich panel on other existing constructions.

Essentially, one of the most important benefits of sandwich panels are their great versatility. They are incredibly practical even for non-professionals and it is an easy-to-use material. It is for this reasons they have become an ideal solution for roofs and interiors, not only for industrial use, but also for residential construction.

Switching asbestos paneling for sandwich panels

Changing asbestos paneling to new sandwich paneling in construction projects involves several steps to ensure a safe and effective transition. Please note that working with asbestos requires specialized training and precautions due to its hazardous nature. It is crucial to consult with licensed professionals or asbestos removal experts to handle the removal process. The following general steps outline the process, but it is essential to adapt them to your specific situation and comply with local regulations.

Asbestos assessment and safety measures

- Risk assessment: conduct a thorough assessment of the asbestos paneling to determine the extent of the presence and any potential risks.

- Contact local authority: comply with local regulations and guidelines regarding asbestos removal and handling.

- Plan your project: establish an asbestos management plan and consult with licensed professionals or asbestos removal experts.

- Obtain necessary permits and approvals: check with local authorities and obtain the required permits and approvals for asbestos removal and construction activities.

Asbestos paneling removal

- Follow proper safety procedures, including wearing personal protective equipment (PPE) such as disposable coveralls, gloves, respirators, and safety goggles.

- Isolate the work area by sealing off adjacent spaces and covering the floors, walls, and other surfaces with protective sheets.

- Wet the asbestos paneling using a water spray bottle to minimize the release of asbestos fibers into the air.

- Remove the asbestos paneling carefully, ensuring it remains intact and minimizing breakage.

- Place the removed asbestos paneling in designated sealed containers for disposal as hazardous waste.

- Thoroughly clean the work area using appropriate methods, including wet wiping and HEPA vacuuming, to remove any asbestos fibers or dust.

Site preparation

- Inspect the underlying structure and ensure it is in a suitable condition to receive the new sandwich paneling.

- Repair or replace any damaged or deteriorated areas of the building's structure as necessary.

- Prepare the surface by cleaning it thoroughly and ensuring it is free of dust, debris or any remnants of the asbestos paneling.

Installation of sandwich paneling

- Select the appropriate type of sandwich paneling based on the specific requirements of the project, such as insulation properties, structural support and aesthetic preferences.

- Follow the manufacturer's guidelines and recommended installation techniques for the chosen sandwich paneling.

- Install the panels according to the building's design and layout, securely fastening them to the underlying structure.

- Ensure proper insulation, weatherproofing, and sealing to maintain energy efficiency and structural integrity.

Post-installation measures

- Conduct thorough inspections to verify the quality of the new sandwich paneling installation.

- Address any necessary adjustments or repairs promptly.

- Dispose of any construction waste, including packaging materials, in accordance with local regulations. Learn about how to get rid of construction rubble with our related article.

Remember that the above steps provide a general overview, and the specific requirements and processes may vary depending on the project, building regulations and local laws. Always consult with professionals experienced in asbestos removal and construction to ensure safety and compliance with applicable regulations.

If you want to read similar articles to What Is a Sandwich Panel Used for in Construction?, we recommend you visit our Ecology (other) category.